testing knife blade hardness|knife blade material chart : distribution The Rockwell Hardness Scale is a clear way to measure how hard a knife is, which helps keep quality standards high across the business. If you understand this scale, you’ll be able to make smart decisions and pick the . WEBUpToDate, electronic clinical resource tool for physicians and patients that provides information on Adult Primary Care and Internal Medicine, Allergy and Immunology, Cardiovascular Medicine, Emergency Medicine, Endocrinology and Diabetes, Family Medicine, Gastroenterology and Hepatology, Hematology, Infectious Diseases, .

{plog:ftitle_list}

WEBNeste ano, foram dez acidentes com vítimas e nove sem. Foram 13 vítimas no total, sendo uma das delas fatal e as outras 12 leves. O carnaval voltou a registrar vítima fatal em .

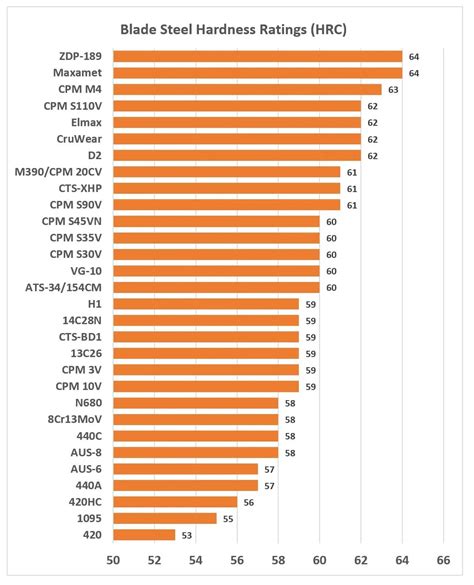

The Rockwell Hardness Scale is a clear way to measure how hard a knife is, which helps keep quality standards high across the business. If you understand this scale, you’ll be able to make smart decisions and pick the .The Rockwell test helps knifemakers balance the three most important factors that can affect the quality of their finished product: hardness, flexibility, and toughness. Regardless of its intended use, any good knife should have a hardness rating between 52 HRC and 64 HRC. Super-hard knives are great for kitchen duties where accurate, thin slices must be made regularly. Softer . In different terms, the Rockwell hardness scale tests will show you how strong the knife blade is for any particular kitchen knife, and that number is often stamped or printed on the blade or handle. Typically, the Type C .

The Rockwell scale was cocreated by Hugh and Stanley Rockwell in the early 20th century to test the hardness of different materials. There are several different scales by which a material’s hardness is measured on, but .The Rockwell hardness test allows knifemakers to find a balance that promotes blade sharpness and helps the owner keep it that way. Generally, a knife with a Rockwell Hardness Scale rating of 58-60 will hold an edge better than a blade . In this advanced knife making tutorial, I discuss why knife makers should test the hardness of their blades and demonstrate how I use the Ames Model 1 to test blades in my shop. How to use Rockwell Hardness Files for knife making. Testing files can be used as an affordable way to test the hardness of knife blades after heat treating..

Today, the Rockwell Hardness Scale is the standard method used to measure and determine the strength and quality of a kitchen knife blade. How Is it Measured? The Rockwell Hardness Scale determines the hardness of a .Mohs hardness test: When conducting the test, place the unknown specimen on a table top and firmly hold it in place with one hand. Then place a point of the reference specimen against a flat, unmarked surface of the unknown . The Mohs hardness test kit is a scratch-testing kit with all the minerals in the Mohs Hardness Scale except diamond. Why? Diamond is expensive and needs mounting on a handle since it’s small. . Knife blade: .

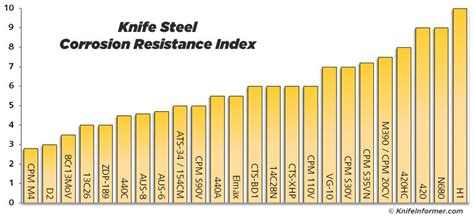

This number helps consumers understand the knife's potential for edge retention, as well as its ability to withstand impact and wear. Understanding the Rockwell Hardness Values: Soft Blades (Low Rockwell Hardness): .A Rockwell hardness tester. The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). [1] There are different scales, denoted by a single letter, that use different loads or indenters. The tool we use to test hardness is called the Rockwell hardness tester. The Rockwell hardness tester applies an indentation force to the material being tested and measures the depth of penetration to determine its hardness value. . This method is widely accepted for testing corrosion in knife blades. It’s a commonly used and standardized .

You can read about my CATRA edge retention testing in this article. Each steel was tested with a knife that was produced just for the test, and then sharpened the same way for each test (15 dps 400 grit CBN sharpening). A few steels have been added since such as MagnaCut and M398. I also added a few more steels in this study. The studies . With Uddeholm’s testing of the similar Vanadis 4 Extra with wear resistance testing, they found no difference between low and high tempering when compensated for hardness [7]: In our case we had a bit higher hardness with the low temper of 4V but the edge retention was only slightly better, perhaps indicating that the 1000°F led to better .Higher hardness value means a longer service life of the blade, because the longer a knife remains sharp (when used correctly), the less it must be sharpened. The biggest benefit of harder knives is long-lasting sharpness and a thin blade. Hardness of 60+ HRC allows a smaller sharpening angle and, consequently, less force is needed for cutting. Mineral hardness tests can be performed at home or on a rockhounding field trip. There are necessary tools for express hardness testing: A fingernail, a Cooper coin (penny or 1,2.5 cents euro), a shard of glass, and a knife blade. You already have two of the tools required for the Mineral Hardness Test!

steel hardness scale for knives

The hardness of a knife is very important as far as its performance and durability. For instance, a harder steel with a RC of 58-62 will hold an edge better than a softer steel. . One small drawback for testing a knife blade is that it leaves a small pinpoint indentation on the blade surface, which some might think is a flaw or defect. The . HRC Rockwell Test - DIY Hardness TestUsually, harder steel increases the likelihood that blade will remain sharp for a longer period of time. Steel hardness .16pc Steak Knife and Bistecca Plate Set + 8" Chef's Knife + 3.5" Paring Knife Bundle 9.99 4 22% Savings (157) Aprons Aprons. Eco Modern Apron Benny's Eco Modern Apron Shop all Aprons > View product detail Eco Modern Apron (Ecru) (22) View product detail Eco Modern Apron (Slate) (22) .One test I talk about a lot in my previous articles is the paper test. For me, this is the easiest and best way to test the sharpness of your knife. All you will need for this test is your knife and a piece of paper. To do this test, try slicing the paper with your knife. If the knife catches the paper and slices it easily, you have a sharp blade.

Hardness testing can be applied to various types of materials, some of which are listed below: Metals and alloys. Ceramics. Elastomers. Polymers and plastics. Films. Rocks and minerals. Importance of Hardness Testing. Hardness testing is important for a number of different reasons. The hardness of a material can be a critical parameter in its .

Scratch hardness and Rockwell hardness are two different things. You can't determine Rockwell hardness with a scratch test or vice versa. However, the scratch test isn't completely worthless, pass/fail or anything like .

Basically, they are files hardened to different specific hardnesses and you see at what point they start cutting your blade/test piece. Most otjer testing wont necessarily give you a number, but it can still be useful. A classic blade test is a brass rod test where you sharpen a blade then roll the edge on a brass rod. Considerations When Choosing a Knife Steel Blade Hardness and HRC Ratings. . The hardness level of steel is determined using a universal scale called the “Rockwell C Test”, commonly called the Rockwell hardness .

The file test is a simple yet effective method for testing knife blade hardness. It involves using a set of files with known hardness levels to scratch the blade. The file that can scratch the blade determines the hardness level. Step-by-Step Guide to File Test.Shop the easy to use Hardness Testing Files from Jantz Supply and quickly test your knife hardness on the Rockwell C Scale. Shop Jantz for all your knifemaking needs. . Knife Blades and Kits; Handle Materials; Shop All Products. Mega. Jantz Supply Digital Catalog. Blade Steel; 01 and W1 Drill Rod; 15N20 2% Nickel Steel; Tool Steel;

As a knife maker, you may have used a hardness tester to perform hardness tests on your knives or saw blades. Ames portable hardness testers are a preferred model for blade makers to perform quick hardness tests. Many knife makers may not have the budget to purchase a new Ames Portable Hardness Tester. Used testers available on eBay and .

For rock-chopping, a Western-style knife with a curved blade and lower hardness (around 56-58 HRC) may be ideal, offering more flexibility and ease of sharpening. If you prefer tap-chopping or push-cutting, a Japanese-style knife with higher hardness (60-63 HRC) could better suit your needs, providing superior edge retention and precision.

The BESS Universal certification provides the expected test results (sharpness ratings) for common types of blades when used with the Edge-On-Up tester: Double-edged razor blades measure between 50 and 80 grams. New utility blades (box cutters) measure between 150 and 200 grams. New blades on common knives measure between 250 and 375 grams.The Rockwell hardness test uses a conical indenter and is the most common test used for testing the hardness of different types of steel. However, the Rockwell test is not ideal for uneven materials with high levels of inconsistency across the surface. . Having enough toughness is vital for cutting tools, as it allows the knife or blade to . The Mohs scale of mineral hardness consists of 10 minerals used for the scratch test. Also, tools like glass or a knife with known hardness can be used for this test. What is Determined by a Scratch Test. A scratch test determines the hardness of minerals according to the Mohs relative hardness of minerals scale.

Using This Test For Knives. The hardness of a knife blade is an important factor in its performance. A blade, that is too soft, will not hold an edge, while a blade, that is too hard, may be brittle and prone to chipping or breaking. The hardness of a blade is determined by the type of steel used and the heat treatment process used to harden . As far as testing, I think touching the edge gives us a pretty very good idea of a blade’s condition, but to see if the knife cuts I test it on something I am going to toss in the recycling bin or try to slice and dice some fruit or veggies. Even if the cut is rough, you can cook or eat the food. I like to cut scrap cardboard.

Hardness and hardness testing is way overplayed. Testing the edge with a file will tell you it hardened, Testing the blade with a brass rod test will tell you if the HT was good. No home smith needs a hardness tester. A lot of full time professional knifemakers have one, but many don't. They are way down on the list of must haves in knifemaking.

how to test arm torsion strength

rockwell hardness scale knives

7 de fev. de 2024 · Veja os melhores sites de apostas para UFC, confira dicas exclusivas, bônus para UFC, melhores Odds e muito mais sobre apostas no MMA. Casas de Apostas Comparativos

testing knife blade hardness|knife blade material chart